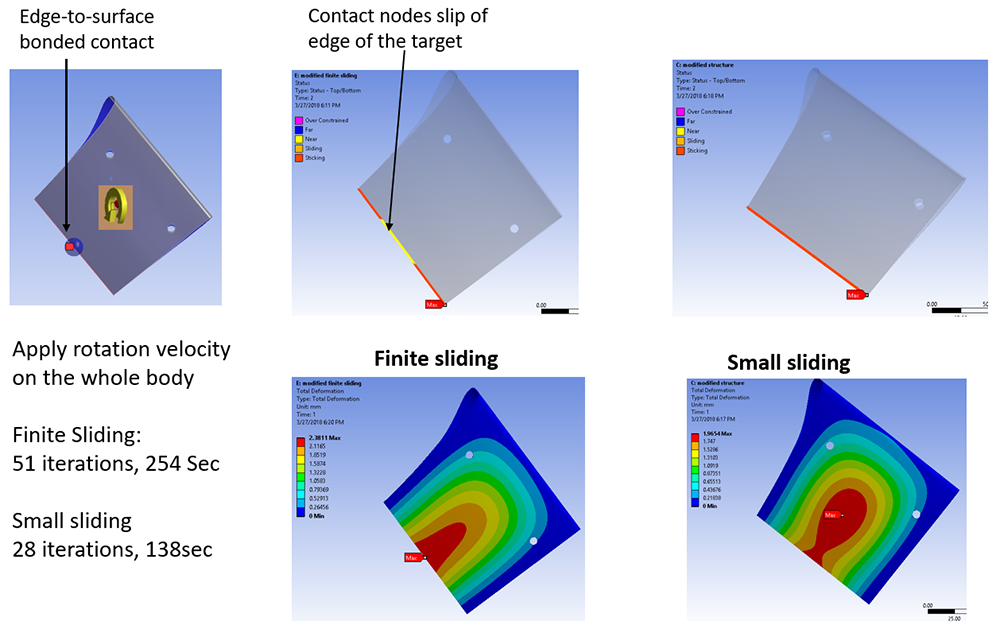

Bonded contact is not useful when you have large relative motion between two solid bodies. FEA User Beware!I don't know if default ANSYS bonded contact is the right setting for the analysis or maybe another one like frictionless between phalanges and pinsfrictional, etc.?. Leave a Reply Cancel reply Enter your comment here Fill in your details below or click an icon to log in.Įmail required Address never made public. Comments 2 Trackbacks 0 Leave a comment Trackback. You are commenting using your Facebook account. You are commenting using your Twitter account. You are commenting using your Google account. More articles like this please on the subject of numerical simulations. I would like to thank author of the article as well. This kind of simple explanation is hard to come by these days. Slide is possible, but the nodes in contact are bonded to the target surface in normal direction. No separation contact: Once the contact is detected, then the target and contact surface are tied up for the rest of the analysis. This behavior can simulate the contact opens and closes. There are several kinds of contact used in ANSYS: frictional, frictionless, rough, bonded, no separation and so on.Ĭontact surface has different types of behavior according to different characteristics of contact. For the surface-surface contact, it is the first step to specify which is contact surface and which is target surface.Īlso when the size of one body in contact compared to another one is very small and then the large surface is chosen as target. Collisions are treated as if the contact is frictionless regardless the friction coefficient.One can not exist without the other. By default the friction is not applied during collision. The tangent force is proportional to the normal contact force. In this setting, a tangent resisting force is applied at each contact point. Cool historical events to write aboutįorced Frictional Sliding should be used instead. The coefficient of friction can be any nonnegative value. Once the shear stress is exceeded, the two geometries will slide relative to each other. In this setting, the two contacting geometries can carry shear stresses up to a certain magnitude across their interface before they start sliding relative to each other. This case corresponds to an infinite friction coefficient between the contacting bodies. By default, no automatic closing of gaps is performed. Similar to the frictionless setting, these setting models perfectly rough frictional contact where there is no sliding. Weak springs are added to the assembly to help stabilize the model in order to achieve a reasonable solution. The model should be well constrained when using this contact setting.

#Ansys contact types free#

A zero coefficient of friction is assumed, thus allowing free sliding. This solution is nonlinear because the area of contact may change as the load is applied. Thus gaps can form in the model between bodies depending on the loading. This setting models standard unilateral contact that is, normal pressure equals zero if separation occurs. Separation of the geometries in contact is not allowed.

It only applies to regions of faces for 3D solids or edges for 2D plates.

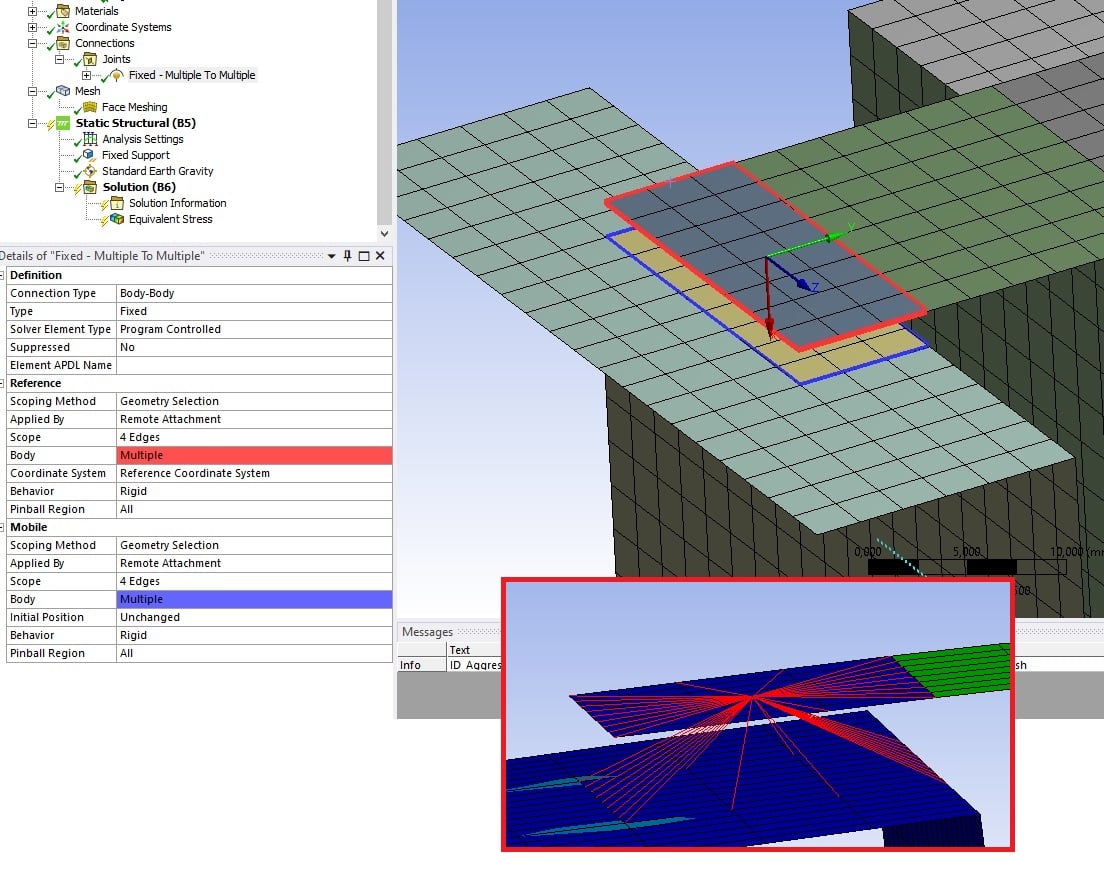

This contact setting is similar to the Bonded case. If contact is determined on the mathematical model, any gaps will be closed and any initial penetration will be ignored.įixed joint can be used instead. If contact regions are bonded, then no sliding or separation between faces or edges is allowed. This is the default configuration and applies to all contact regions surfaces, solids, lines, faces, edges. Most of the types apply to Contact Regions made up of faces only. The available contact types are listed below. If convergence problems arise or if determining the exact area of contact is critical, consider using a finer mesh on the contact faces or edges. However, using these contact types usually results in longer solution times and can have possible convergence problems due to the contact nonlinearity. Choosing the appropriate contact type depends on the type of problem you are trying to solve.

0 kommentar(er)

0 kommentar(er)